As a contractor specializing in the preservation of historic buildings, Mason Lord has been a fan of Bensonwood for many years. After Unity was spun off of Bensonwood in 2012. Mason followed the new company’s development with interest.

We first met Mason in 2018 at a green building conference in Boston, where he expressed interest in being a local builder on Unity projects. What he didn’t mention at the time was that one of the projects he had in mind was the construction of his own home. Eventually that’s the direction the discussion took, and in October of 2020, we assembled the shell of Mason’s Zum-style home on a wooded knoll in Sharon, CT.

Teaming Up With Unity

Why would a general contractor opt to work with Unity instead of building the entire home with his own crew? For Mason there were several reasons, including not having the time to spare to frame his new home, not wanting to figure out or re-invent the high-performance details that are standard for Unity, and not wanting the construction schedule to slide from months to years. Having Unity provide the shell allowed us to do what we do best, and Mason’s team members to focus on their respective specialties.

Design

As with any project, the design of this home began with the site. Mason spent many hours walking the wooded property to familiarize himself with the features, the topography and the light. A wooded knoll halfway up a long hillside emerged as the best place for the house. It was level enough that, with a fair amount of site work, he could install a slab foundation. And the lovely view that he planned to open up to the south would justify the expense of the long, curved driveway. With the setting of the house identified, Mason engaged a site planner to finalize the location of the septic system and well.

Unity’s Zum design platform couldn’t be more different from the historic homes that Mason has worked on for most of his career. That’s exactly why he was drawn to the Zum – because it is so different. Mason’s taste in design – and that of his wife Hope – is broad. When it came to interior design, they pushed the envelope. We love the brightly colored interior doors, the lime green tile backsplash, and the contemporary cabinets, light fixtures and artwork.

Construction

Being a builder, Mason had a deeper appreciation than most Unity clients for the quality of the shell that our crew assembled on site. He’s a big fan of our thick super-insulated walls, the triple-glazed tilt-turn windows and the airtight construction. He was also in a great position to provide helpful feedback as he and his crew finished the shell. While the interior partition walls that Unity provides typically save time on site, Mason found that due to changes he made to the design, he ended up reworking a number of walls. In retrospect, he thinks that it would have been better if he had framed them all himself. He also had good suggestions for tweaking the interior framing details to facilitate the work of subcontractors.

The heating and cooling equipment for this house is typical for Unity: a Mitsubishi air source heat pump. Mason opted to install a fully-ducted system, so as not to have wall or ceiling cassettes.

The system for heating the domestic hot water is made by a company called Sanden, and it’s a bit unusual. Although the system is based on the same air source heat pump technology that’s increasingly common in water heaters, this unit locates the compressor outside of the house, and uses CO2 as a refrigerant. Interestingly, CO2 has a much lower global warming potential than the refrigerants typically used in heat pump water heaters.

Finishes and Fixtures

Mason drew on his extensive construction experience when choosing fixtures and finishes. The recessed lights feature “tape in” grilles that have a clean, seamless look. The shower pan in the primary bathroom was recessed into the slab, allowing for a curbless shower. The kitchen counters are made of sintered stone, an engineered material that’s more durable and heat-resistant than most natural stones. Mason used cutoffs from the counters to form durable sills for the exterior doors. Several of the brightly-painted closet doors are set up on precision-engineered rollers that allow them to glide smoothly to open and close.

SQUARE FOOTAGE

Total Living Area: 1,798 SF

2 Car Garage: 24′ x 28′

ADDITIONAL FEATURES

6’ x 8’ Entry Porch, 12’ x 12’ Screened Porch, Mudroom, Exterior Decks

BUILDING SHELL

Wall Insulation: R-35

Roof Insulation: R-50

Foundation Insulation: R-15

Windows: Logic triple pane tilt-turn; U 0.15

Air Tightness: 0.8 ACH50

MECHANICAL SYSTEMS

Heating/Cooling: Mitsubishi air source heat pump

Water Heater: Sanden heat pump water heater

Ventilation: Honeywell ERV

Renewable Energy: Solar PV on garage

Home Performance

Because this home is oriented toward views and sunlight to the south, the roof is pitched down toward the north, making it less than ideal for photovoltaic panels. Mason opted for a solution chosen by the owners of other south-facing Zums, having us build a garage in the style of the house, but oriented so that the roof would work well for solar panels. Those panels are now providing most of the power consumed by the house.

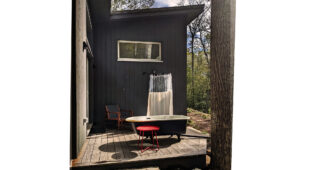

After a year in the house, Mason and Hope are very pleased with how it’s performing. They also love the way that the house nestles into its surroundings. The exterior decks are perfect for “forest bathing” – and there’s an outdoor shower and tub on one of the decks for actual bathing. The screened porch adjacent to the kitchen gets lots of use during spring, summer and fall.

Although this project was only the second new home that his company has built, Mason is looking forward to future collaborations with Unity that will bring more high-performance homes to northwest Connecticut.