Unity Blog

- All

- Building with Unity

- Design

- Energy & Efficiency

- News & Events

- Projects

- Sustainability

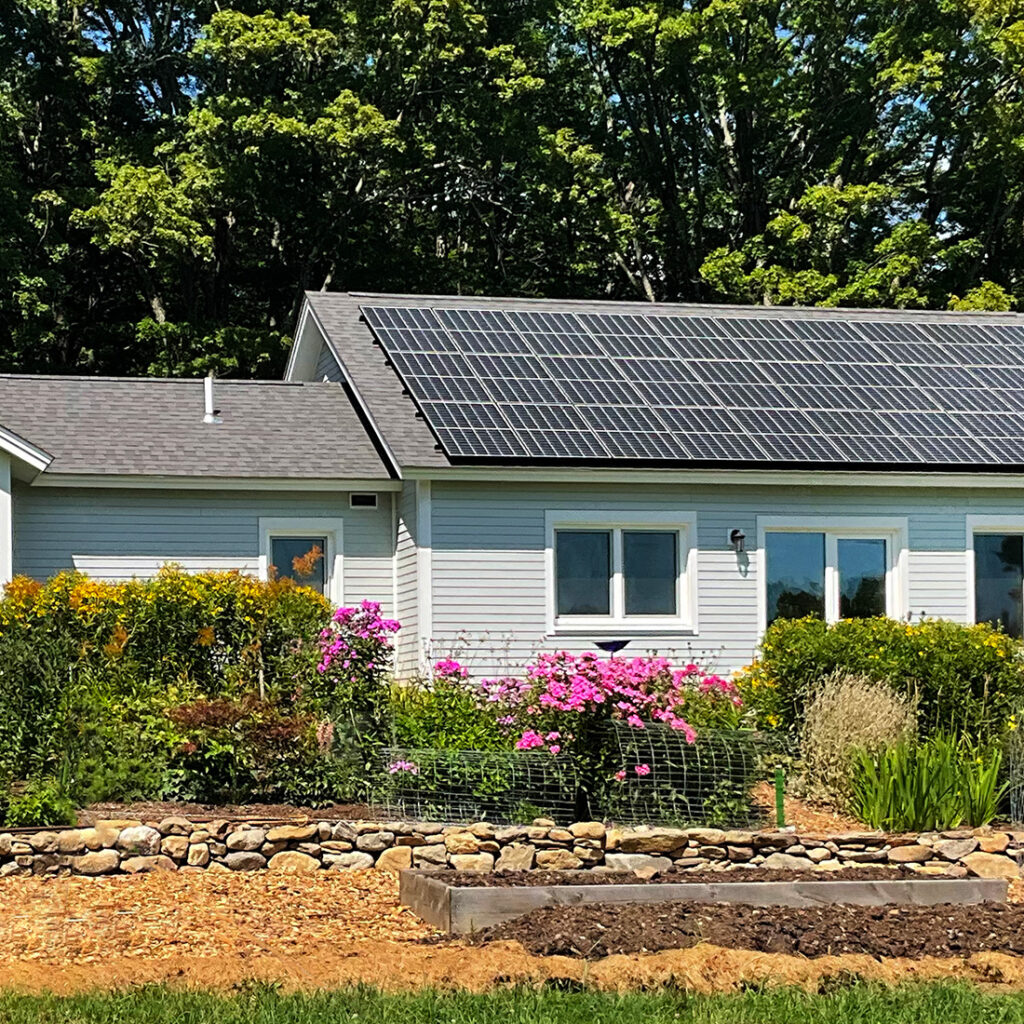

Building with Unity, Energy & Efficiency, Sustainability

Sustainable Homes from a Solar-Powered Factory

Read more

Energy & Efficiency, Sustainability

Why All-Electric Homes Are Better for You and the Planet

Read more

Energy & Efficiency, Sustainability

Passive House Standards with Unity

Read more

Building with Unity, Design, Projects

Building Small, Living Big: A DIY Nano Adventure

Read more

Building with Unity, Design

Unlocking the Advantages of Panelization in Island Construction

Read more

Building with Unity, Projects

Streamlined: How Unity Homes Is Reinventing Home Design

Read more

Building with Unity

How Unity Helps Homeowners Find and Select a Local Builder

Read more

Building with Unity

Local Builders on Unity Projects

Read more

Projects

A Xyla in Alstead, NH

Read more

Energy & Efficiency

Build New or Retrofit an Existing Home?

Read more

Design

Unity’s Selection Process: Finishes and Fixtures

Read more

Building with Unity

Where Unity Builds

Read more

Design

Unity’s Screened Porches

Read more

Projects

A “Zumette” in Mystic, CT

Read more

Building with Unity, Energy & Efficiency, Sustainability

Why Build Now

Read more

Projects

A Zum in Sharon, CT

Read more

Projects

A Xyla in Wellfleet, MA

Read more

Projects

A Nano in Springfield, VT

Read more

Design

Unity Garage Design

Read more

Projects

Four Värms in Hanover, NH

Read more

Projects

A Värm in Hanover, NH

Read more

Projects

3 Nanos in Brewster, MA

Read more

Projects

A Zum in Waterbury, VT

Read more

Energy & Efficiency

A Healthier Way to Cook

Read more