Anyone considering having a new home built faces a fundamental question: whether to pursue a path based on off-site construction (generally panelized or modular), or have the home built in a more typical manner, with the countless individual parts and pieces fashioned and fastened on site. Good results can be obtained with either path, because the key factors are the knowledge, experience, dedication and cooperation of the team building the home. Of course at Unity Homes, we believe that the best results are most readily achieved using off-site fabrication. A growing cadre of industry experts agrees.

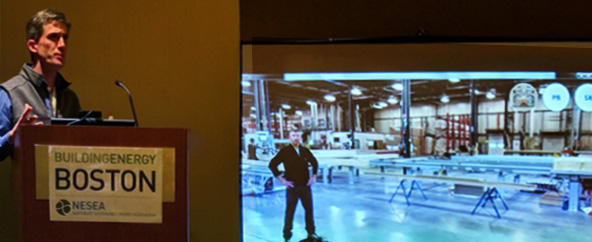

At a recent industry event in Boston, the buzz about off-site construction was palpable. Every year the Northeast Sustainable Energy Association’s “Building Energy Boston” conference brings together professionals dedicated to high-performance building, energy efficiency and renewable energy. Presentations featuring off-site construction figured prominently at the conference, including two in which Unity and Bensonwood were front and center.

On the first day of the conference, Bensonwood COO Hans Porschitz participated in a panel discussion that reviewed the legacy of a project built in 2007 that helped to spawn three new companies, each focused on using off-site construction to build high-performance homes: Unity Homes, BrightBuilt Home and GO Home.

Before these three companies existed, their founders collaborated on the construction of an innovative building for an adventurous client in Rockport, Maine. That project was the BrightBuilt Barn. The lessons learned on that project and the acclaim it generated helped to inspire Bensonwood to spin off Unity Homes, Kaplan Thompson Architects to form BrightBuilt Home, and GO Logic to create the GO Home. All told, these companies are responsible for designing and building over 500 high-performance homes during the past ten years. And that legacy continues to grow.

A second highlight of the conference, and one that also reinforced the sense that the future of home building is in off-site construction, was the real-time tour of the new state-of-the-art production facility that Unity and Bensonwood share. The roughly 100 attendees at this conference session in Boston were treated to a live remote tour of our new facility in Keene, NH.

The tour was led by Building Systems team leader Jay Lepple, who walked through the shop and explained the equipment, materials and methods that we are using to build high-performance homes. Unity founder Tedd Benson concluded the tour by explaining that the vision of this new facility extends beyond Unity and Bensonwood, because we plan to provide precision building components to other projects and companies as well.

During the Q&A session that followed the tour, the conference-goers in Boston were able to ask questions of our building systems team in Keene. One of the more memorable questions came from a Maine-based architect who asked “How will you respond when 250 architects suddenly come knocking on your door asking for panels for their projects?” That would be what we call a “good problem”!

Given the quality of practitioners brought together by the NESEA conference, it has always provided a glimpse of the future of sustainable building. This year’s conference reinforced our belief that off-site construction will increasingly be the method of choice for building homes that are healthy, comfortable, durable and efficient.